This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Transforming the Transformable

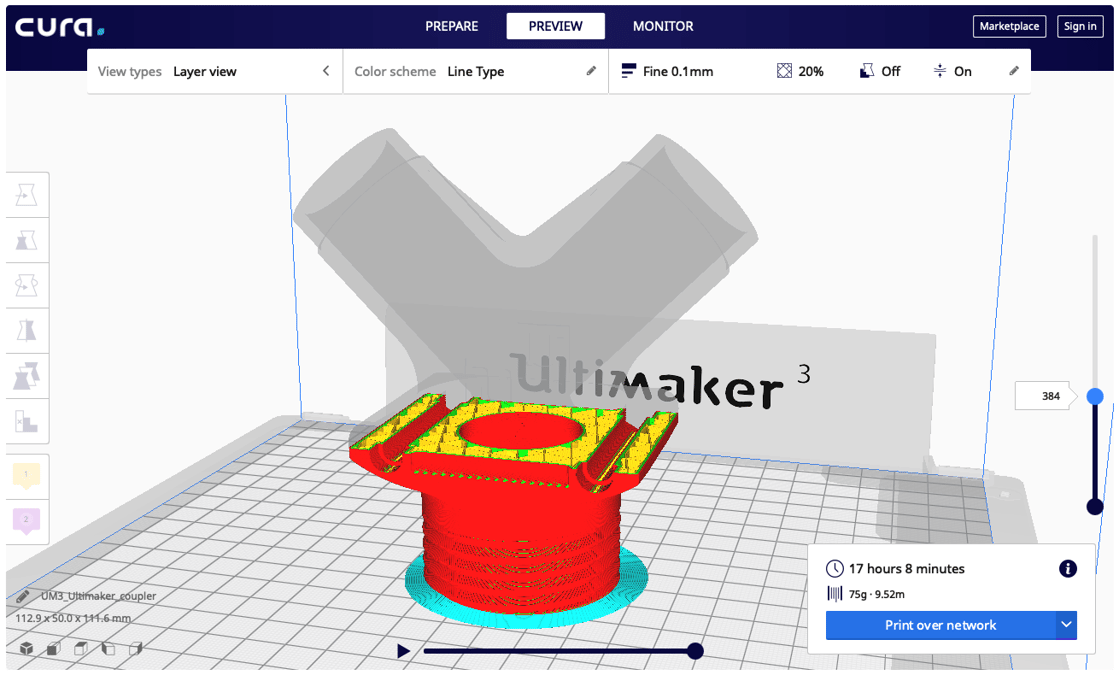

How to Convert STL Files to G-code

STL is a common file format for 3D models. Most manufacturing systems, however, require G-code. Find out how to convert STL to G-code!

Advertisement

Advertisement