This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Print for Profit

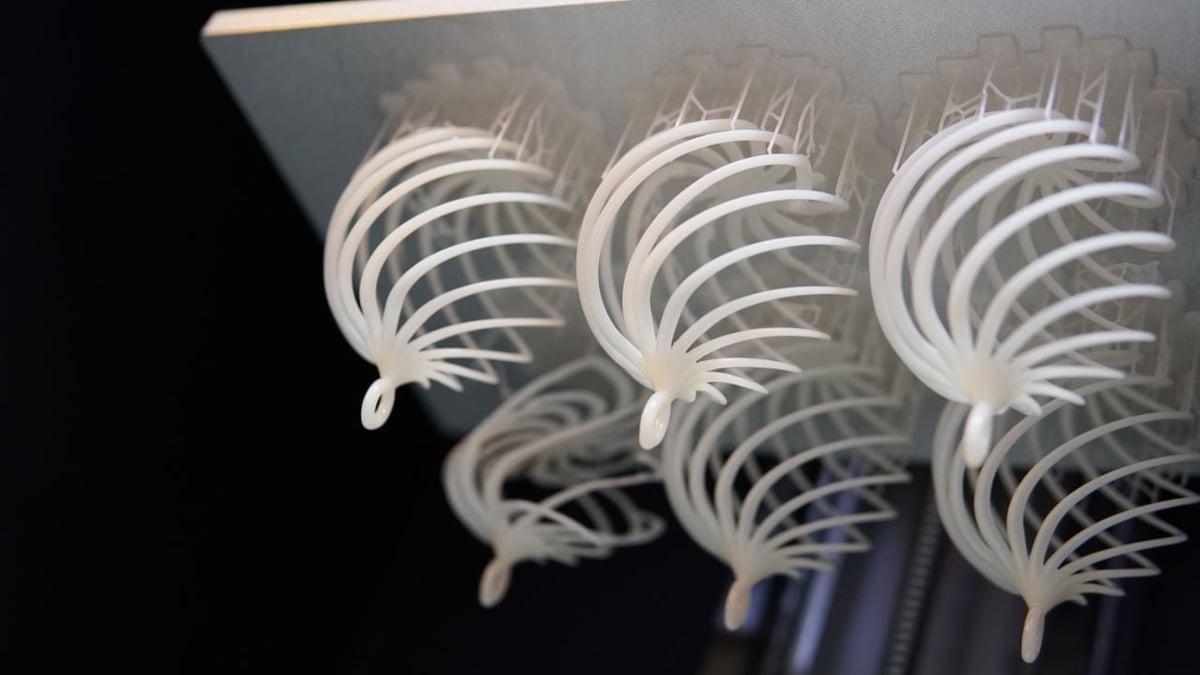

3 Great 3D Printing Business Ideas to Start Your Own

If you want to start a 3D printing business, there's a lot to consider. Read on for ideas to turn your hobby into a lucrative activity!

Advertisement

Advertisement