This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Stick to the Sheet

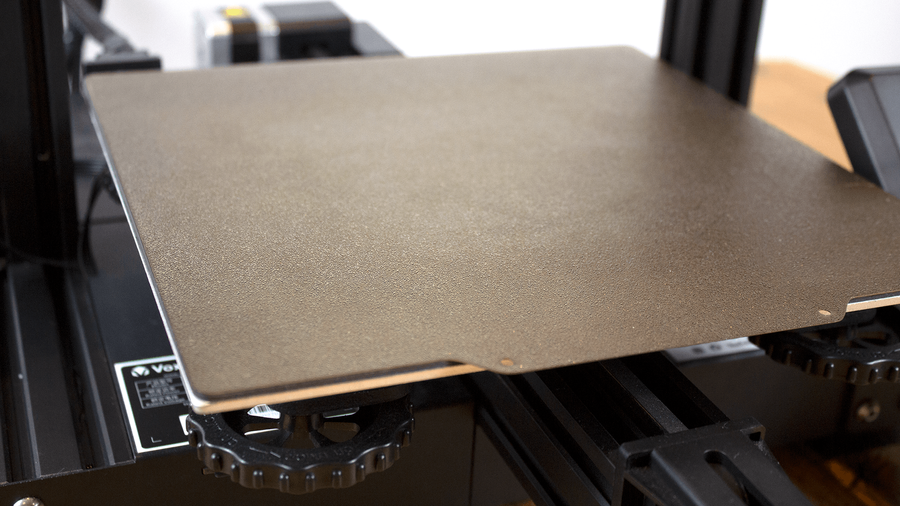

PEI Sheet (3D Printing): How to Use It on Your Print Bed

Fed up with icky glue sticks and blue tape? Learn how to apply a PEI sheet to your print surface to obtain the optimal 3D printing results.

Advertisement

Advertisement