This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Twice the Fun

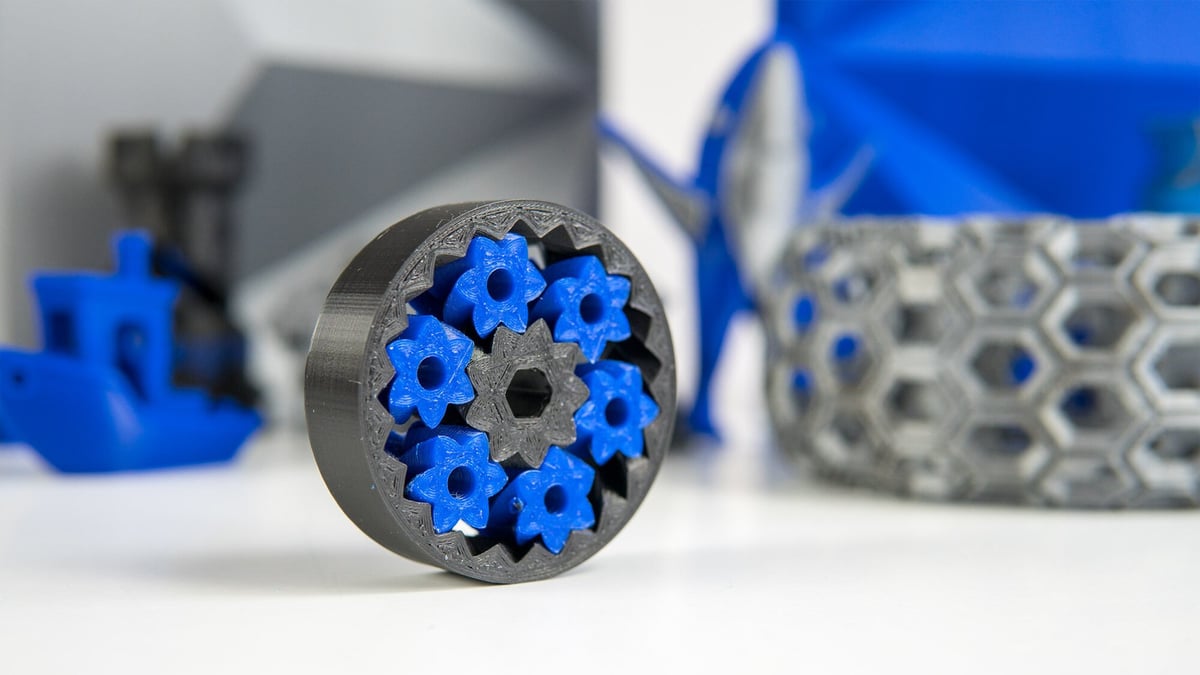

Dual Extruder (3D Printing): All You Need to Know

Double the possibilities with dual extruder 3D printing! Read on to learn all about dual extrusion, how to do it, and tips for pretty prints.

Advertisement

Advertisement