This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Nests Aren't Just for Birds!

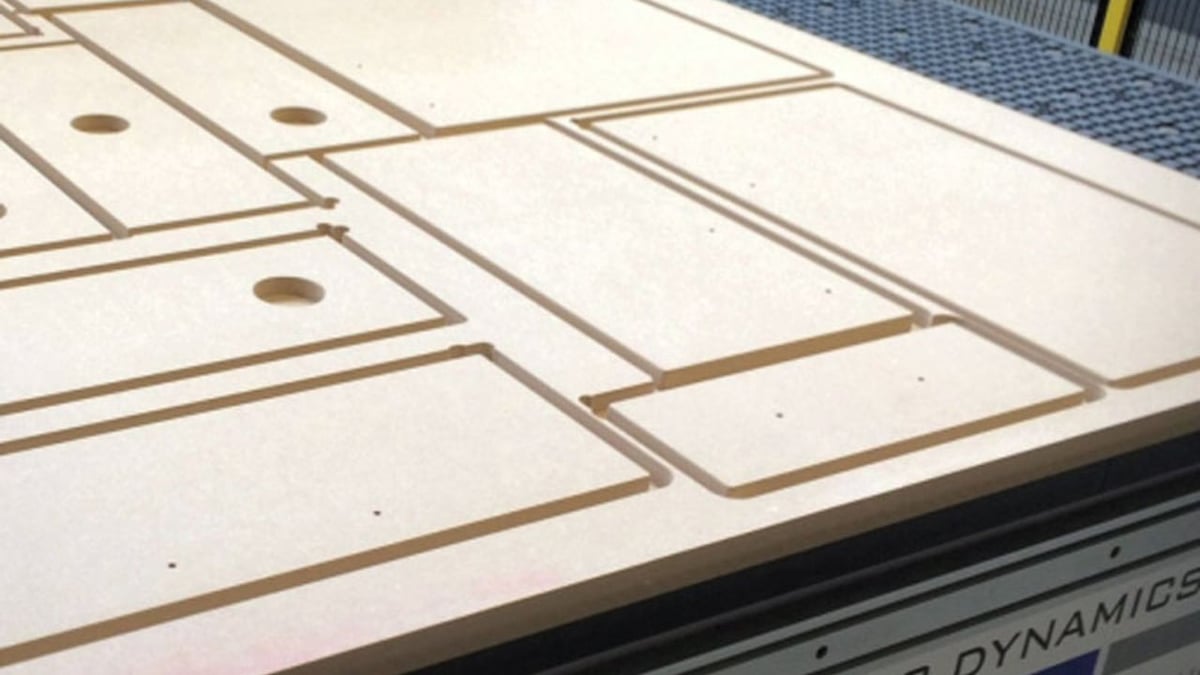

CNC Nesting (CNC Cutting Method) – Simply Explained

Nesting is an important aspect of production, ensuring work is completed efficiently in terms of time and material. Read all about it.

Advertisement

Advertisement