This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Support Is All You Need

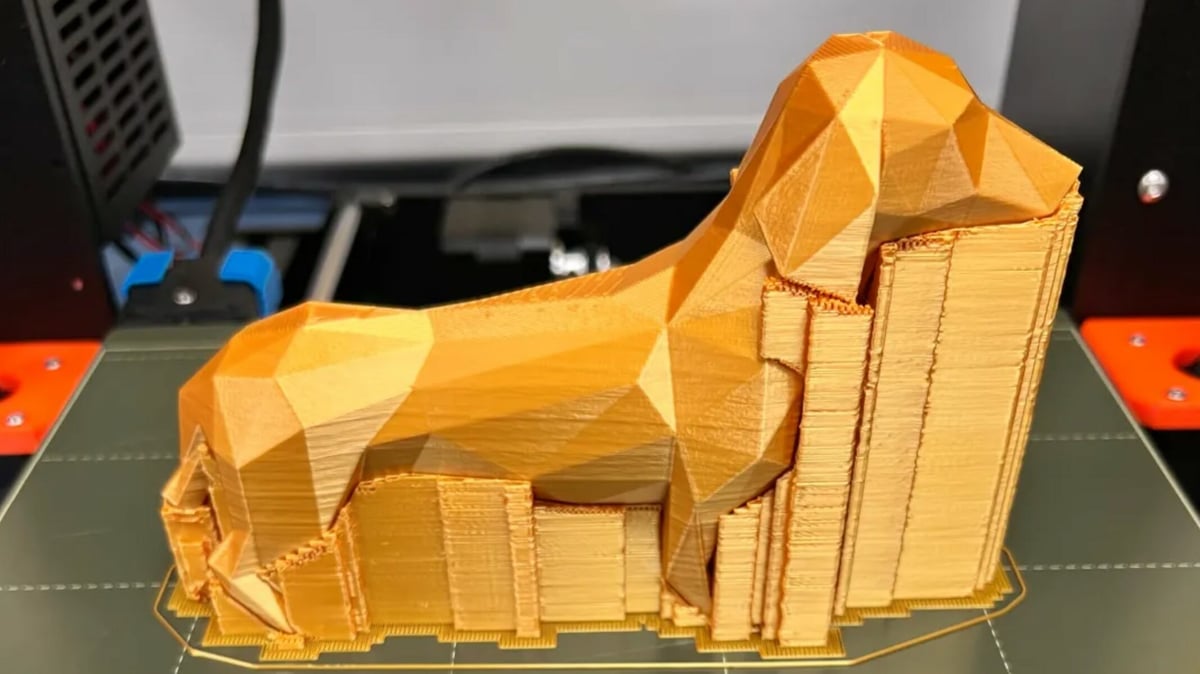

3D Printing Supports: 3 Simple Steps to Success

3D printing supports are often essential when dealing with a difficult model. Let's go over support types as well as settings for success!

Advertisement

Advertisement