This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Keep It Together

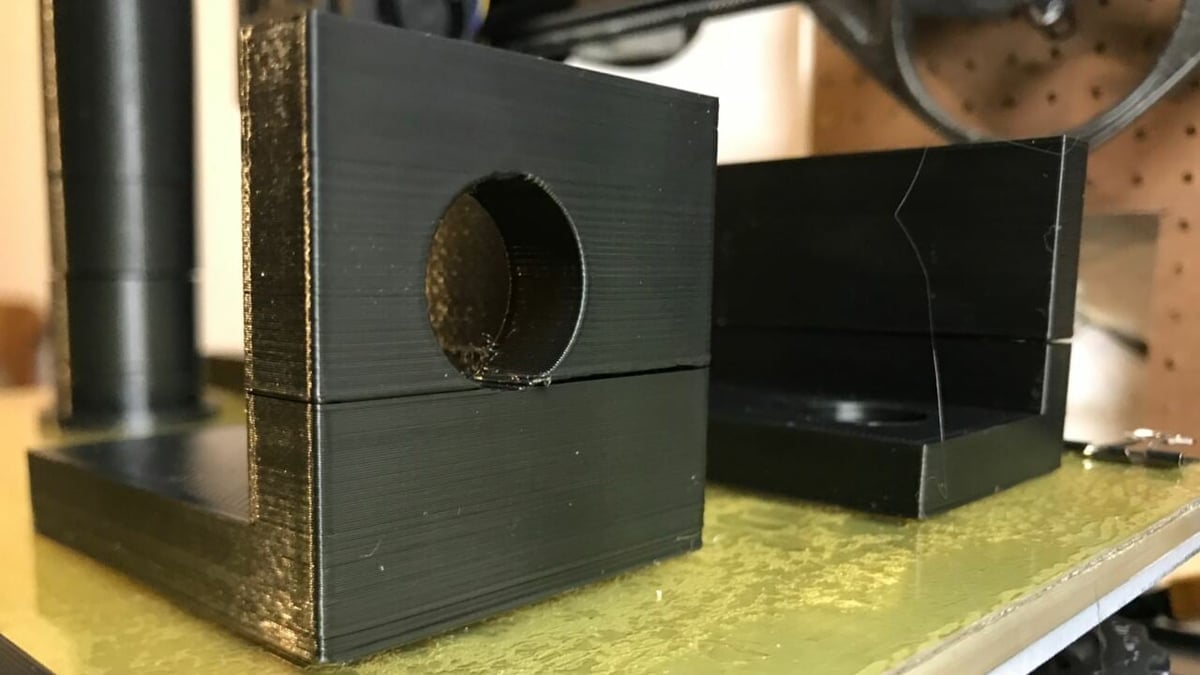

3D Print Layer Separation: 8 Tips to Avoid Delamination

If you're experiencing 3D print layer separation, we've got some tips. Read on to find out how to get those layers to stick!

Advertisement

Advertisement