This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

It's All Engravy

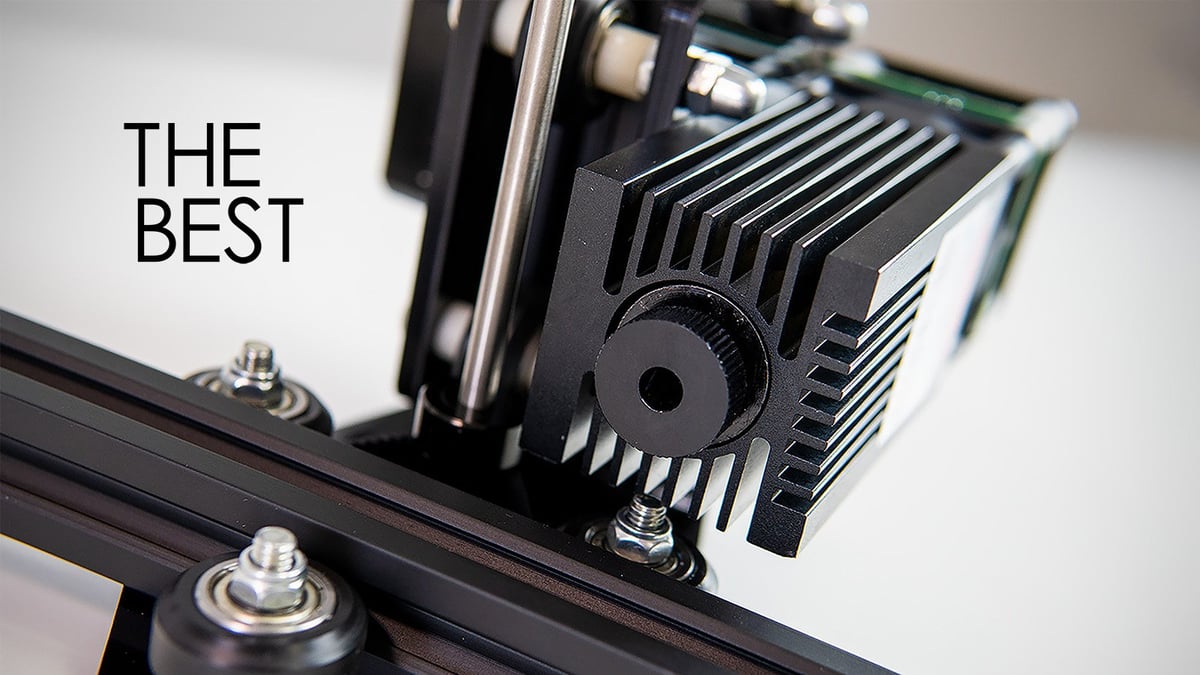

The Best Laser Engravers in 2024

Get fired up for our picks of the best laser engravers on the market. Plus, a short guide to engraving and materials.

Advertisement

Advertisement