This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Keep in Touch

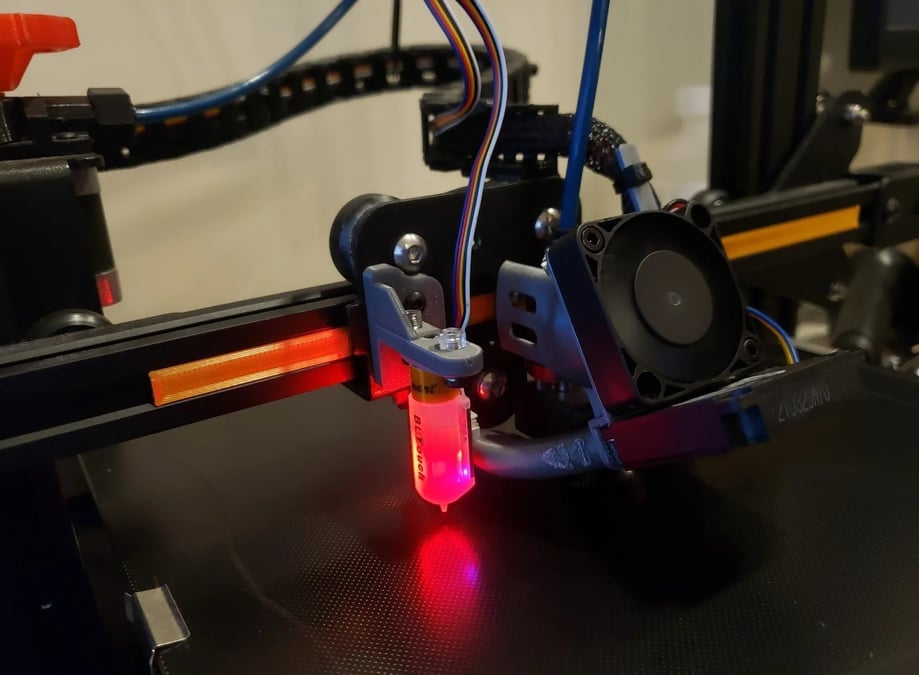

BLTouch Sensor: All You Need to Know

A BLTouch sensor will automate your 3D printer bed leveling. Read on to learn all you need to know about the BLTouch!

Advertisement

Advertisement