This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Extruding Knowledge

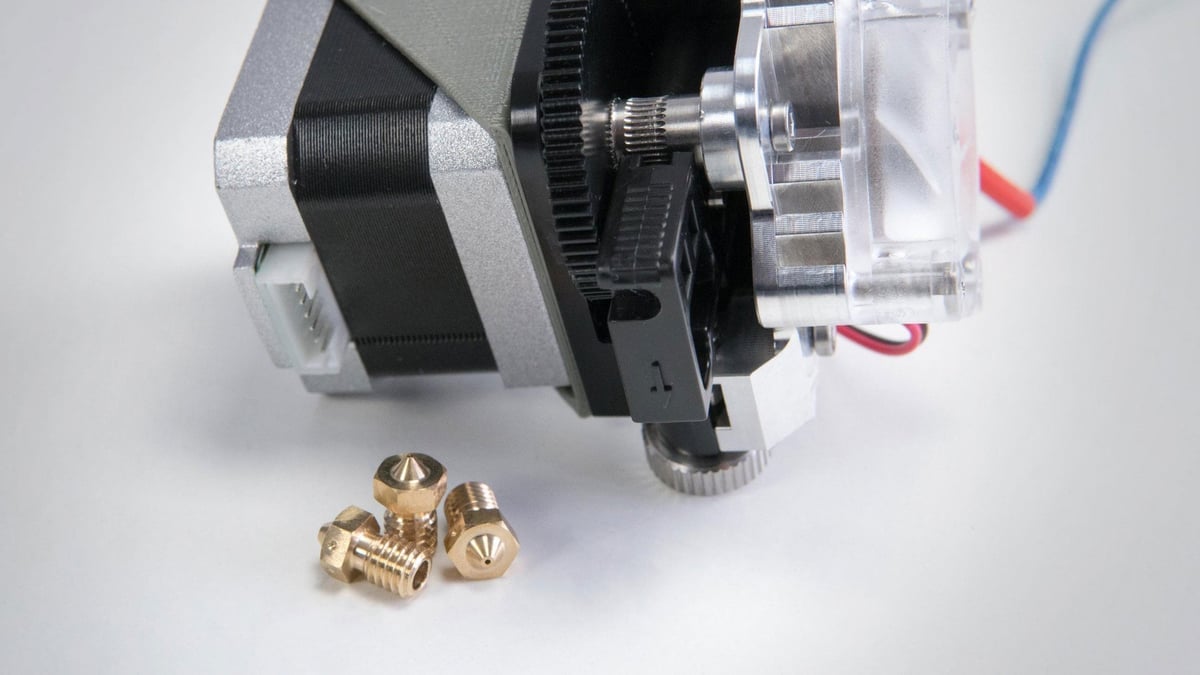

3D Printer Extruder – All You Need to Know

Learn the basics of direct and Bowden 3D printer extruders, hot and cold ends, and geared extruders, plus nozzle sizes, materials, and uses.

Advertisement

Advertisement